InBrief · 30 Dec 2025

From Seawater to Bioplastic

From Seawater to Bioplastic

Oceans absorb about one-third of atmospheric carbon dioxide emissions, but converting this dissolved inorganic carbon into useful products has remained a major challenge. A research team led by Dr. GAO Xiang from the Shenzhen Institutes of Advanced Technology (SIAT) of the Chinese Academy of Sciences and Dr. XIA Chuan from the University of Electronic Science and Technology of China has now developed an artificial oceanic carbon recycling system that captures CO2 from seawater and directly converts it into succinic acid—a key building block for biodegradable plastics.

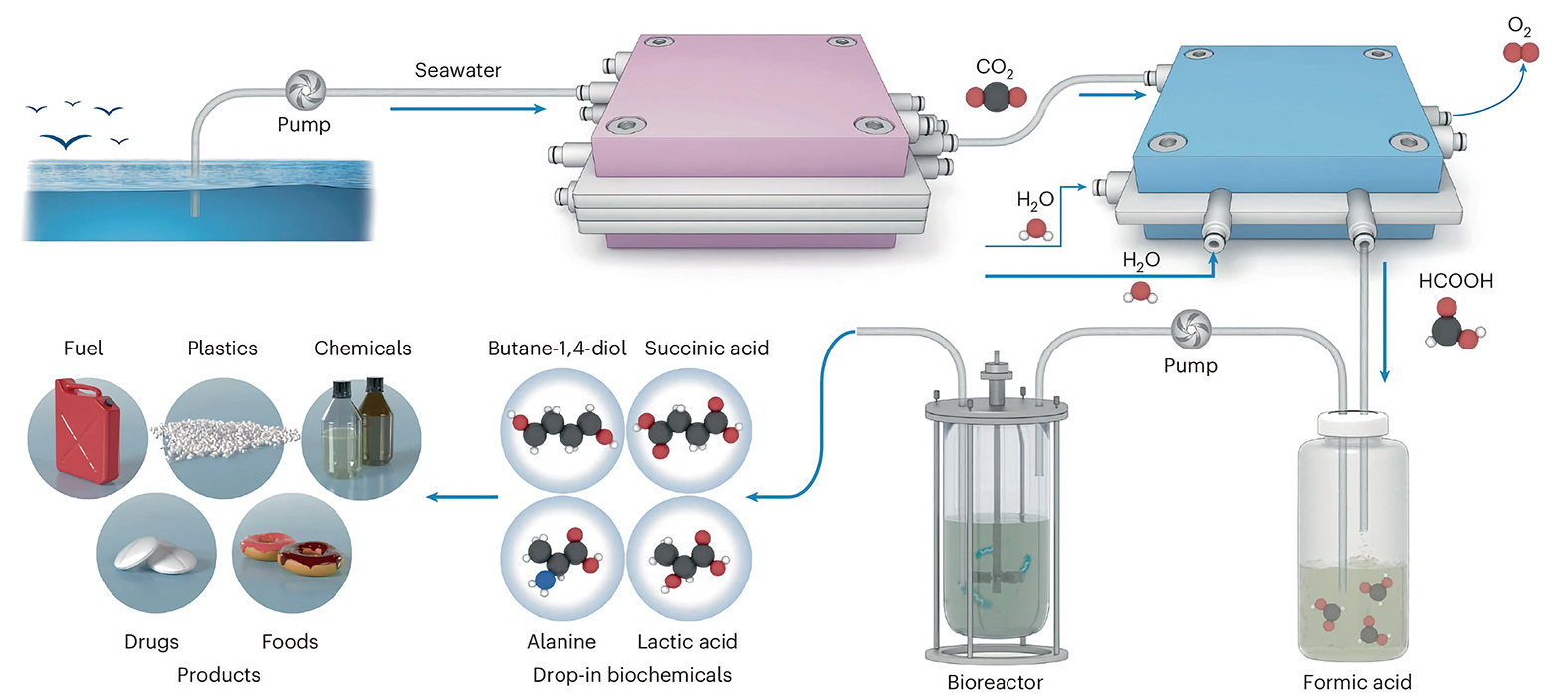

As reported in Nature Catalysis (doi: 10.1038/s41929-025-01416-4) on October 6, 2025, the system combines electrochemistry with microbial fermentation in a cascade process. Seawater flows into a five-chamber electrochemical reactor where an electric field generates protons that acidify the water, converting dissolved carbonate into gaseous CO2. A hollow-fiber membrane separates the CO2 and delivers it to a second reactor containing a bismuth-based catalyst that reduces CO2 to formic acid. Finally, an engineered strain of Vibrio natriegens ferments the formic acid into succinic acid. The system operated continuously for over 530 hours using natural seawater from Shenzhen Bay, achieving a 70% efficiency of carbon capture—far exceeding previous devices that typically run for only a few hours. The estimated capture cost of approximately $230 per metric ton of CO2 is competitive with current carbon capture technologies. By incorporating different engineered microbes, the platform can produce various industrial chemicals including lactic acid, alanine, and 1,4-butanediol. This study presents a sustainable strategy for upcycling ocean-derived CO2, opening new avenues for electrochemically driven biochemical synthesis.

Schematic illustration of the artificial ocean carbon recycling system that captures and converts oceanic CO2 into drop-in biochemicals through decoupled electro-biocatalytic processes.

(Image by SIAT)